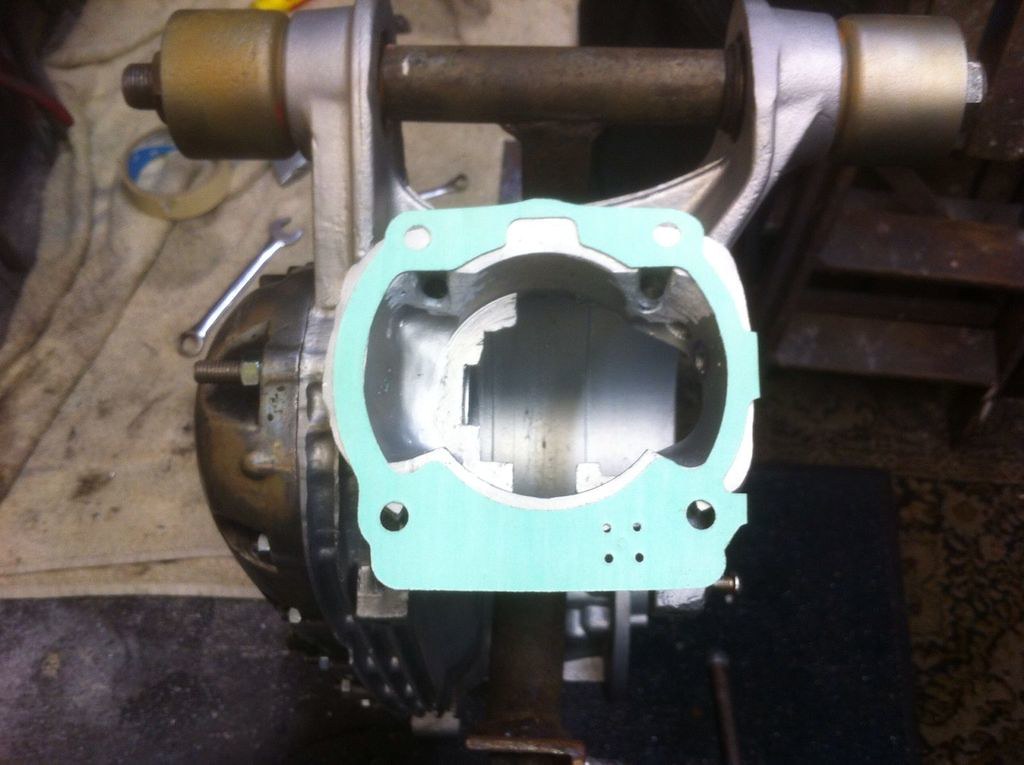

lambretta 290 rotax

hi folks,

bought an old engine case of an auction site last year, i was told it had a rotax barrel fitted, more than that the seller couldnt tell me, he said it was in his loft for quite a few years, and all the other parts, eg barrel and crank got sold by mistake.i think it was an old air cooled version, and i realy want water cooled, heres some pics of the case.

[url][url=https://flic.kr/p/VPi8DY] [/url]dc2ed206334ef21c6e8eec685885452a3_zpsrxokm7xg by stephen holt, on Flickr[/url]

[/url]dc2ed206334ef21c6e8eec685885452a3_zpsrxokm7xg by stephen holt, on Flickr[/url]

[url 632f5d97c38bad262f476b73d5ee7e095_zpsqrha924a by stephen holt, on Flickr][/ur

632f5d97c38bad262f476b73d5ee7e095_zpsqrha924a by stephen holt, on Flickr][/ur

[url][url=https://flic.kr/p/V8anL5] [/url]8ff6f18d4604d05a50f65d5f00cb43ad1_zpsftur22vo by stephen holt, on Flickr[/url]

[/url]8ff6f18d4604d05a50f65d5f00cb43ad1_zpsftur22vo by stephen holt, on Flickr[/url]

bought an old engine case of an auction site last year, i was told it had a rotax barrel fitted, more than that the seller couldnt tell me, he said it was in his loft for quite a few years, and all the other parts, eg barrel and crank got sold by mistake.i think it was an old air cooled version, and i realy want water cooled, heres some pics of the case.

[url][url=https://flic.kr/p/VPi8DY]

[/url]dc2ed206334ef21c6e8eec685885452a3_zpsrxokm7xg by stephen holt, on Flickr[/url]

[/url]dc2ed206334ef21c6e8eec685885452a3_zpsrxokm7xg by stephen holt, on Flickr[/url][url

632f5d97c38bad262f476b73d5ee7e095_zpsqrha924a by stephen holt, on Flickr][/ur

632f5d97c38bad262f476b73d5ee7e095_zpsqrha924a by stephen holt, on Flickr][/ur[url][url=https://flic.kr/p/V8anL5]

[/url]8ff6f18d4604d05a50f65d5f00cb43ad1_zpsftur22vo by stephen holt, on Flickr[/url]

[/url]8ff6f18d4604d05a50f65d5f00cb43ad1_zpsftur22vo by stephen holt, on Flickr[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]

[/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]

[/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url] [/url]

[/url]