crank induction Malossi 221

My aim was to do a reed crank induction on my Lambretta. Thinking it was a waste using a Lambretta barrel (the carb' inlet needing to be blocked off) i decided to use a Vespa 221 MHR, which was cheaper than most Lambretta kits

I had a spare Spanish 150 casing out of a 76' Li and a solid series 2 Spanish frame for the new engine to go in. I also had some MK 2 Vijay forks that i wanted to use. This was my basis for the build but there was plenty of bits still to buy.

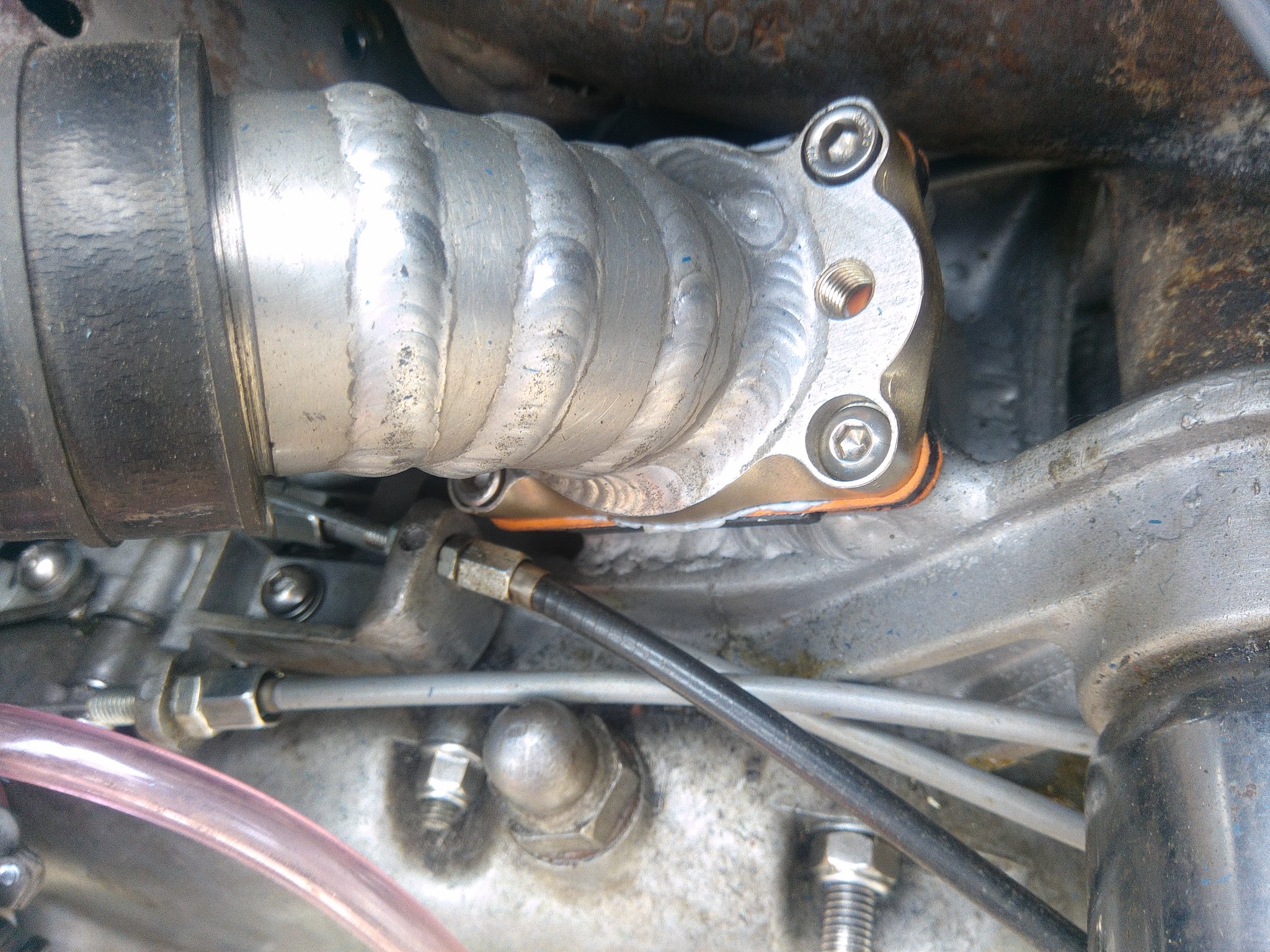

I started this just before Christmas 2018 when i approached a local engineer with regards to the welding and machining required. He said he needed the crank and a reed block would be easier than making our own, these were duly purchased (107x60 crank) from AF and an MB shorty.

With my brand new MHR kit, reed block, crank and casing i met with the engineer. It was decided to skim the face of the casing then weld a new aluminium "ring" on the end. This was to be 20mm+. The reed block was more of a challenge. We discussed the size of the opening we were going to create and clearance issues with the frame and other engine parts (cable adjuster block for one).

In the new year we had it something like:

IMG_20181228_102240 by mick leaf, on Flickr

IMG_20181228_102240 by mick leaf, on Flickr

IMG_20190109_152549 by mick leaf, on Flickr

IMG_20190109_152549 by mick leaf, on Flickr

IMG_20190107_134622 by mick leaf, on Flickr

IMG_20190107_134622 by mick leaf, on Flickr

IMG_20181228_102230 by mick leaf, on Flickr

IMG_20181228_102230 by mick leaf, on Flickr

IMG_20190119_112139 by mick leaf, on Flickr

IMG_20190119_112139 by mick leaf, on Flickr

IMG_20190109_152604 by mick leaf, on Flickr

IMG_20190109_152604 by mick leaf, on Flickr

IMG_20190109_152609 by mick leaf, on Flickr

IMG_20190109_152609 by mick leaf, on Flickr

Will continue later....trying to show photos rather than links........any ideas ?

I had a spare Spanish 150 casing out of a 76' Li and a solid series 2 Spanish frame for the new engine to go in. I also had some MK 2 Vijay forks that i wanted to use. This was my basis for the build but there was plenty of bits still to buy.

I started this just before Christmas 2018 when i approached a local engineer with regards to the welding and machining required. He said he needed the crank and a reed block would be easier than making our own, these were duly purchased (107x60 crank) from AF and an MB shorty.

With my brand new MHR kit, reed block, crank and casing i met with the engineer. It was decided to skim the face of the casing then weld a new aluminium "ring" on the end. This was to be 20mm+. The reed block was more of a challenge. We discussed the size of the opening we were going to create and clearance issues with the frame and other engine parts (cable adjuster block for one).

In the new year we had it something like:

IMG_20181228_102240 by mick leaf, on Flickr

IMG_20181228_102240 by mick leaf, on Flickr IMG_20190109_152549 by mick leaf, on Flickr

IMG_20190109_152549 by mick leaf, on Flickr IMG_20190107_134622 by mick leaf, on Flickr

IMG_20190107_134622 by mick leaf, on Flickr IMG_20181228_102230 by mick leaf, on Flickr

IMG_20181228_102230 by mick leaf, on Flickr IMG_20190119_112139 by mick leaf, on Flickr

IMG_20190119_112139 by mick leaf, on Flickr IMG_20190109_152604 by mick leaf, on Flickr

IMG_20190109_152604 by mick leaf, on Flickr IMG_20190109_152609 by mick leaf, on Flickr

IMG_20190109_152609 by mick leaf, on FlickrWill continue later....trying to show photos rather than links........any ideas ?