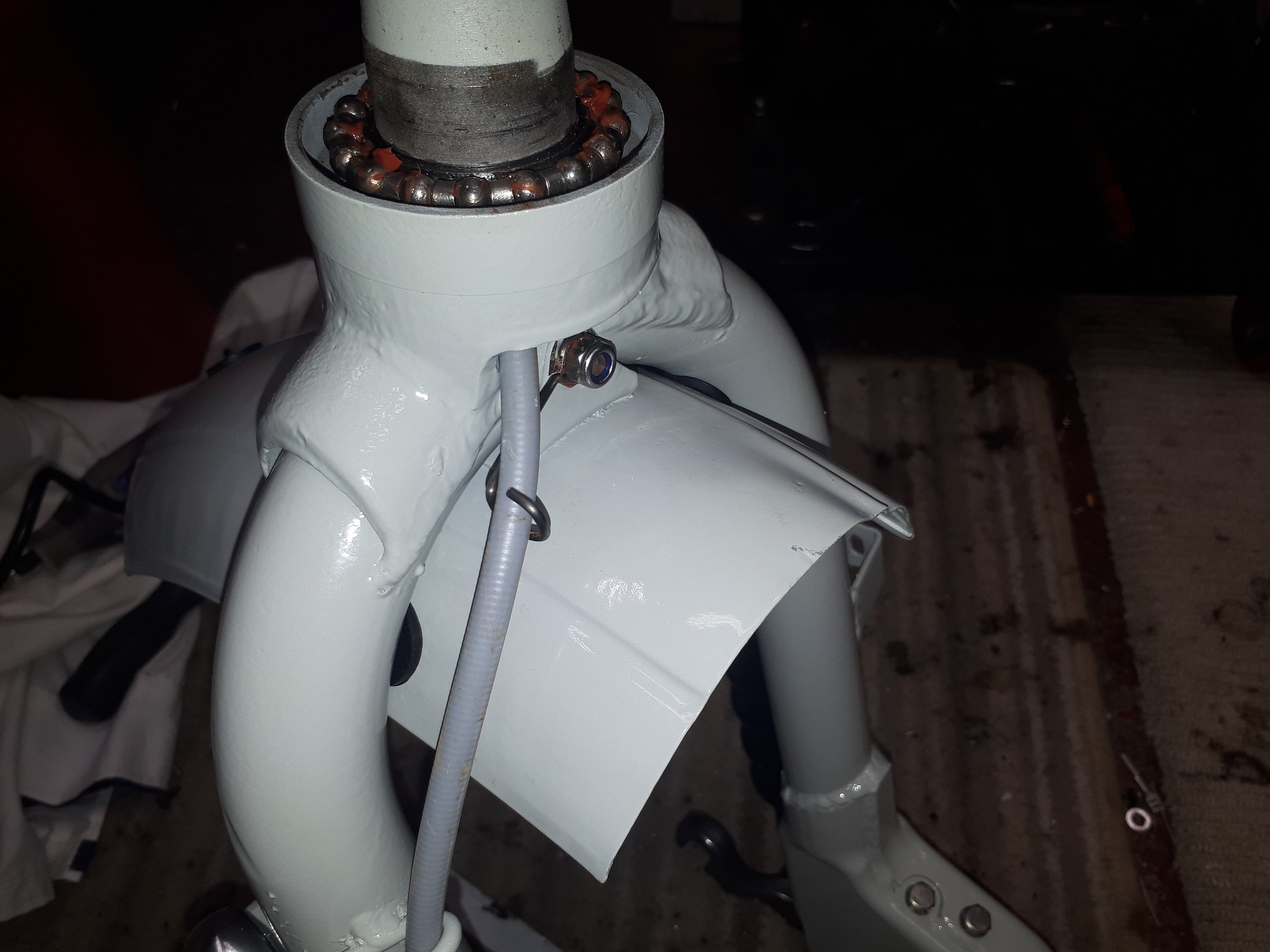

Warkton Tornado No.1 wrote:Excuse the interruption, but whenever I’ve swapped rivets for high tensile socket screws, thus far, I’ve always managed to tap the actual flywheel centre boss to M6. This gives even more clearance & is also marginally lighter

Then it’s just a case of using high tensile button head screws with a dab of Loctite threadlock. As there is often the ring plate (as in the case depicted) additional washers are not required (IMHO)

However, if you are hamfisted, cannot drill & tap square & your test of the correct torque is by stripping the threads(!) then drill through & use nuts on the back....

I'm definitely hamfisted. I think the torque test will be achievable though - what torque setting would you recommend