Pillar drill 3mm bit. Drill through. The holes need to be at the extremity of where the washer would sit, this is to make sure that when you drill the barrel you are not drilling into the barrel stud holes.

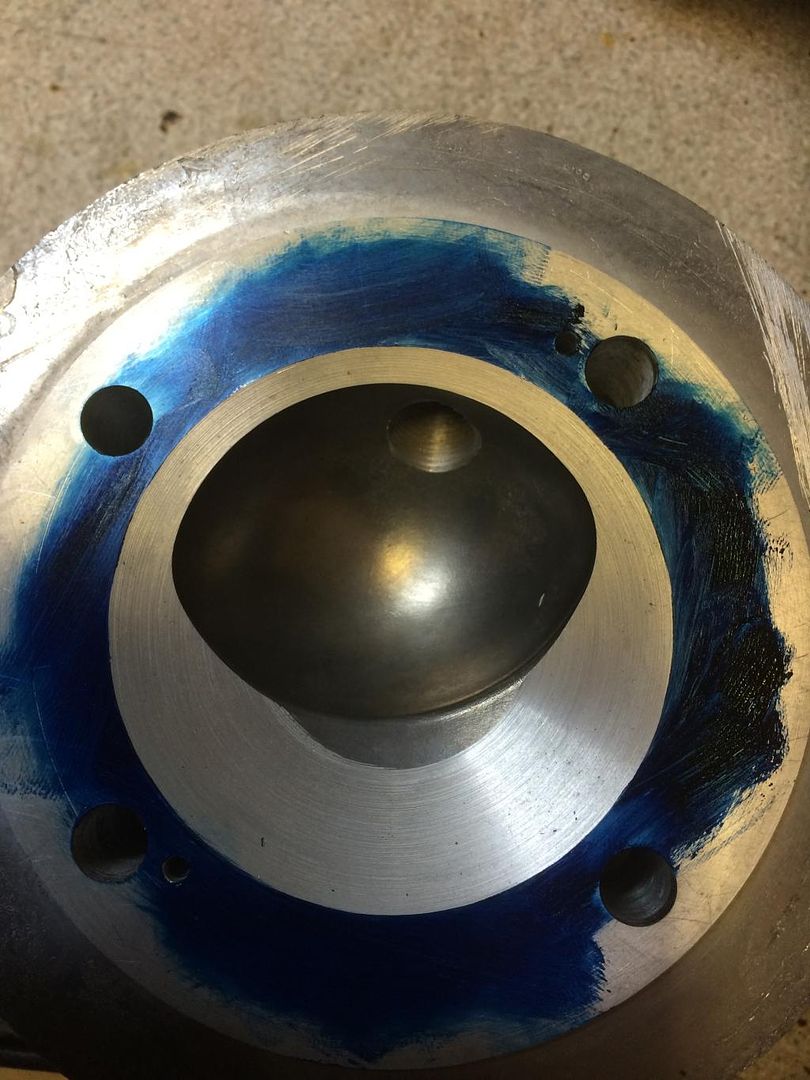

Check position of holes, then mark the gasket face (Only) with engineers blue or marker.

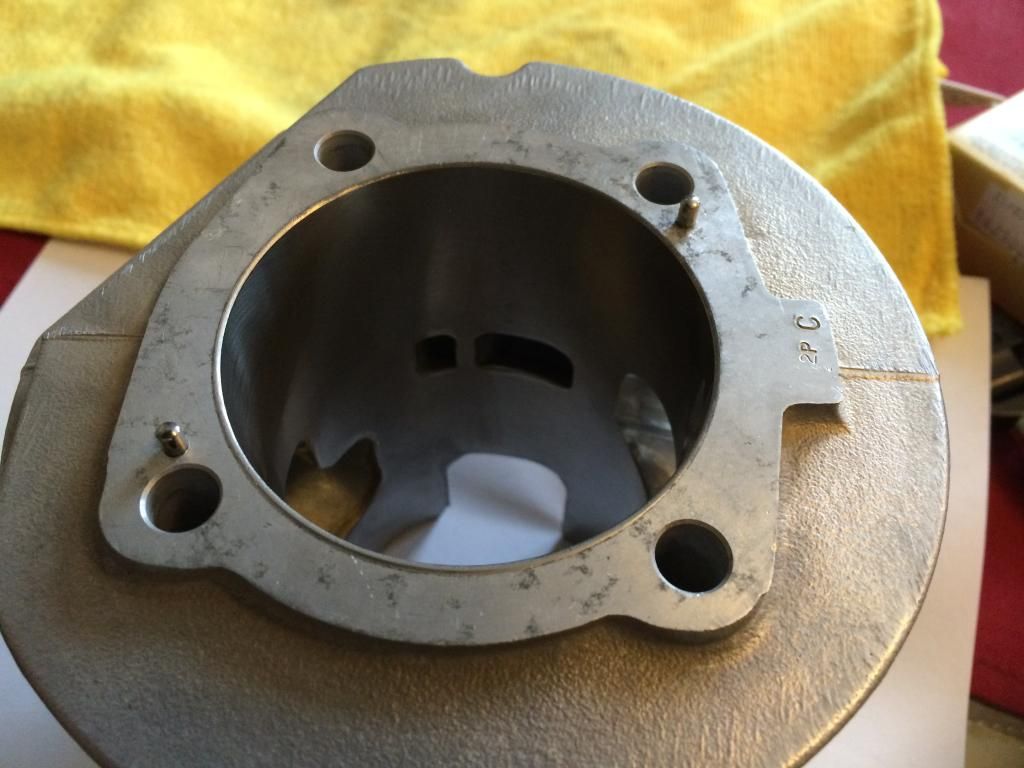

Bolt barrel and head together with four barrel studs 8 nuts and 4 washers.

With the barrel and head bolted up loosely spin the cylinder head fully one way and mark the barrel where it sits, then spin it back the other way and mark it again.

Next centre the head in the middle of the two marks to help align the studs, this will make it much easier to set the head on the barrel later.

Lightly tighten the head nuts, but be extra careful not to damage the spigot of the barrel.

Turn the assembly upside down, so now you can look down the barrel at the cylinder head, now using a very broad rubber mallet lightly tap the head to position it central so that no engineers blue can be seen. The head must be just loose enough to move.

When you are certain that the cylinderhead sits central, tighten all the head bolts.

Now recheck the marks you made earlier, if they are ok you can now remove the two barrel studs that sit over the pre drilled holes in the cylinderhead.

Now your ready to drill. Put the assembly back under the pillar drill and align and drill through to the head.

You need to drill just deep enough to sit the dowels into the head. The pillar drill has a gauge on the side so if you pull the drill bit down through the pre drilled hole now you have a start point, so now you can see how far you are drilling into the barrel.

Do not drill too deep or you will loose the dowels in the drilled holes.

Drill to suit the length of the dowels you use....

I use old crankshaft big-end roller bearings from old cranks I've pressed I find that there perfect for this.

Also a drill press with anything less than 50mm travel will make it difficult to drill to the depth that you need.

You only need a few mm protruding to centre the head, I've left about 5mm. I drilled approx 9mm into the barrel, the dowels sit in about 8mm deep.

Hope this is some use, Mark.