by Adam_Winstone » Sat Feb 20, 2016 10:56 am

by Adam_Winstone » Sat Feb 20, 2016 10:56 am

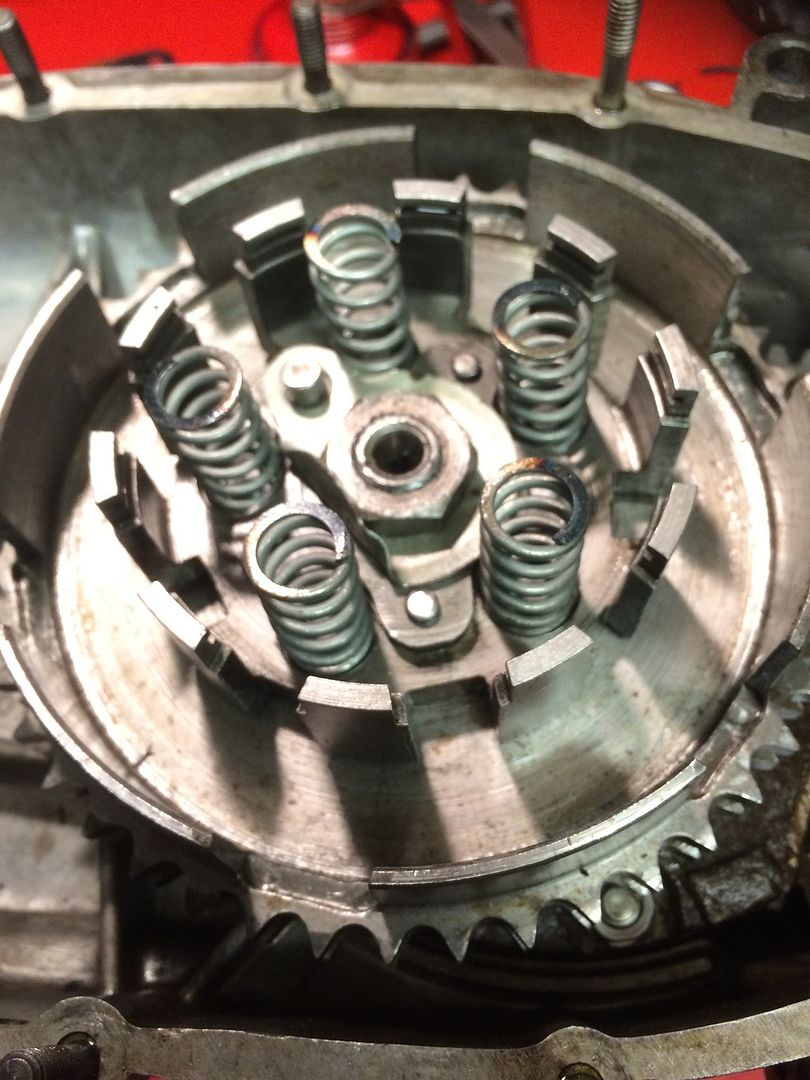

One issue that I found with the early ScootRS spiders that I bought (3 of!) was that the recesses for the bottom of the springs was not machined in the correct alignment for the springs to sit/stand straight when assembled. What I mean by that is the ScootRS spider had the recesses at a different distance from the centre of spider to centre of recesses, which meant that the bottom of the spring was on one alignment and the top of the spring was on another, causing the spring to sit in a 'Z' shape and try to bow when the clutch was compressed. This was fine in a number of mild tune bikes with 5-plate assemblies, however, it soon proved to be an issue with higher power motors.

A couple of key things that I must point out is that the spring alignment was out when used with a selection of original factory pressure plates (Innocenti, Spanish and SIL), and also an MB pressure plate, however, I have never tried a ScootRS pressure plate, which may also have the spring recesses at the same centres as their spider, in which case it would work perfectly well. What this did show was that buy buying different clutch components from different supplies can introduce unforeseen problems. As such, buying a ScootRS pressure plate may well have rectified the issue with the spider, however, I was not in the mood to buy additional (not cheap) parts to find that it was simply continuing to shell out for individual components that didn't align correctly when assembled.

NB: This isn't to have a go at ScootRS, this is more a lesson about buying parts from different sources, and I could just as easily say the same about other expensive clutch components that I've bought in the UK that have also had machining errors that introduced other issues.

IMO you should buy a complete clutch from one supplier so that you can go back to them if you have issue, rather than buying different components in different places and trying to then point the finger at any one supplier.

Adam