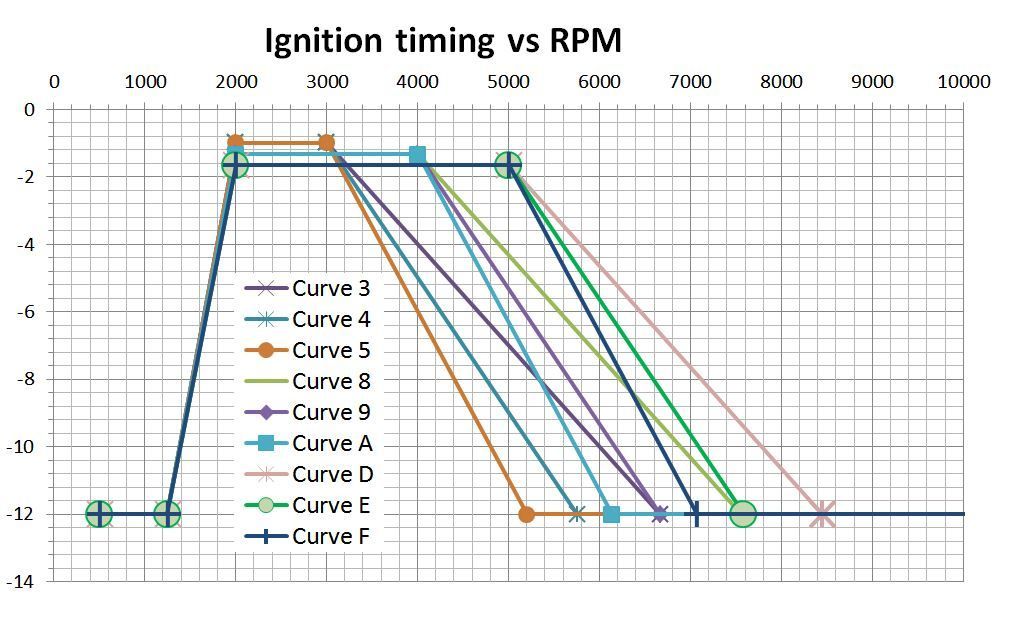

However, Ky-Tronik now have a spread sheet where you can compare curves, see link below. Now I can play about with all the variables on this chart, but first I need to understand the cause and effect of changing these curves. Eden and others have mentioned mapping ignition, but what is it all based on to get your engine running sweet and safe.

Any info would be great for me and I bet many others.

https://drive.google.com/file/d/0ByAeFQ ... selJj/view